Resurrecting A 225 Dodge Slant Six - Engine Power S2, E2

Feb 27, 2020Today, when it comes to

engine

power

, the guys tackle Chrysler's most durable and versatile inline-six with a twist or should we say aslant

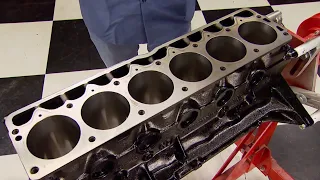

legendary for being indestructible. Today we are going to analyze, rebuild and improve a true American cultengine

, the bulletproof Chryslerslant

-6, why? Surely you are wondering: it is a popular engine. Several of you viewers have been asking us to take a look at its revolutionary inline-six design, tilted 30 degrees off-center to allow for a lower hood profile, lower center of gravity, and more access to engine accessories. since 1959. Through 2000, Mopar produced more than 12 million of these G-Series engines with displacements of 170, 198, and 225 cubic inches, first for the compact Valiant and later as the base engine in more than 25 Dodge and Plymouth cars and trucks. , from darts to diplomats and Belvedere to barracudas, and thank you.Due to its extreme reliability, the slant-6 also served its purpose and dozens of tractors, military trucks, forklifts and industrial applications, we bought this one at the local cemetery for a hundred and fifty dollars and although it won't run like a v8, this leaning tower of Power is high in the cold department, but I think it has some problems: The distinctive unequal length intake runners were mediocre and distributed fuel, but still delivered over 30 miles per gallon and one hundred and forty-five horse

power

at 4000 rpm and a 215 foot torque with plenty of torque. pounds at only 2800 the one ton sequence cracks in six sloping exhaust manifolds were very common this one fits perfectly on the valve cover it has seen better days but it won't go on the scrap pile we will still use all the old cans as covers when it hits a paint job.The next thing to come off is the cannon oil tan. Various versions were made depending on the vehicle they came in and the capacity range from five to six quarts. The pickup is bolted to the block and can also be removed in advance. The balancer can be removed using our Matco puller. The seal steel timing cover is then removed as this was an automobile engine and not a heavy duty version. It has a single highway timing chain. We'll replace everything on the side of the motor, the coil. fuel pump, distributor and engine mount Chrysler fitted this engine with an external gear rotor type oil pump, its design and location made it easy to repair, although not many problems arose.

The 225s were equipped with either a standard volume like this or a high volume one. On heavy-duty models, the valve train features adjustable sheet metal rocker arms with a 1.5 ratio. They are held in place with a shaft, which is how they are lubricated. The cylinder head is constructed of chromium alloy cast iron. Removing the cylinder head bolts in the reverse order of how they were tightened will make the head turn like a banana, let's see what we have for countless years in the salvage yard, let's let this slick 6 soak in plenty of water Unfortunately it's taking its toll now, we don't even know if this block will be useful due to the amount of corrosion at this point, a lot of guys would go ahead and throw this block away but we won't give up and a little destruction doesn't scare us as long as take us to The next step to get the old air chisel out of hiding, we need to see if the factory forged crankshaft will come out without removing the rods, so first we'll remove all the rod caps and then the huge main pipes, now share the same design. and the size of Chrysler's Hemi v8, you're all set, yeah, oh, that's going to make it a lot easier for cylinders one and two.

They came out relatively easily because the valves of those cylinders were closed, maintaining the water rudder. Hey, it cleans the hole pretty good on the way out. We progressed, as did the degree of difficulty, but it came out with a bit of vibrational coaxing hmm. Wow, number four was the most stubborn. The pistons move, they don't go down there, they swing. Our efforts weren't working, so we'll have to get more. aggressive with it and before we fully blow out the piston with a chisel we'll put a flat plate on the rod and tap down to see if we can get it loose, yeah honey I can't believe the last two had the most corrosion and build up on the cylinder, well we have no idea how many miles, so you could have millions of miles on it, so I'm a little sick and tired of vibrating, let's get that last one out and then we'll talk about it. man I love it, I love science, I love discovery, they moved easier than three and four, but the rust cloud told the whole story by taking the pistons off the top and gave us a better, cleaner view to verify the condition of these cylinders as far as possible. we can say they may be salvageable, the water pump is mounted with a side offset which helped keep the engine as short as possible now they had a known issue, the shaft being outside the pump, oh man that's childhood diarrhea , the camshaft is standard six-cylinder fare that rides on four cam bearing journals and has the Drive distributor in the middle now being upgraded for a livelier grind from Comp Cams the last thing we're going to do is move on and wash this block before sending it to the machine shop which will give those guys a head start with a clean part, it can't be rebuilt until the machine shop says we're back and it's been a week since we shipped our slant- 6 to the machine shop but it didn't come back, the machine shop found a lot of things wrong with it and it was just completely unusable, so let's move on with this one before we start putting it together with some layers of duplication.

The engine's ceramic enamel color and Chrysler red were in order. The original crank had a crack in the radius of the rod journal on the number one cylinder, which is automatic cause for replacement, as our plan is to have a street-grade Slant-6 with excellent drivability and forging . The crank will be overkill for the application, so a cast crank like this will be strong enough for the RPM and power we are going to be making. Matching rods were also needed for that cast crank, since it is now large and narrower in the forging. The crank was much wider but they share the same lengths from center to center.

The first model block had three freeze plugs on the side. This is a later version and has five dimensions. There are no differences in the ingredients for this build. They're all affordable bolt-on parts you can buy from Summit Racing names like Hooker, pioneer of Comp Cams Edelbrock, and Houser will often help us make more power, even if he's fresh out of the machine shop. It is always good practice in engine building to check your tolerances as this is not a high tech racing engine these measurements will be a little more forgiving first we will check the main bearings our replacement crank was cleaned to ten thousandths of an undersize in the mains I'll use a Mike two to three to set the exact size of the journal now, the main number one can be filled with a bearing and tightened into place.

I will set the dial gauge using the microphone and check the main torque to measure the clearance. I'll repeat this for the other main three as well. Never assume the chains will always be fine, you also have a larger window of acceptable bearing clearances, unlike a true racing engine, all crank journals are then measured and the same procedure is used to check the oil clearance for the connecting rod bearings. We'll tighten the rods with a special vise and then use the bore gauge to check all of their clearances if you've never done this before. Here you have interesting information.

You should know the factory bearing clearances for a slant-six in both the main and rod bearings. varies from two ten-thousandths to twenty or ten-thousandths, it is a range of mm that is enormous by machining standards. The hours arrive almost dead in the middle, which is just what we want. The rear main seal I'm putting on is something special available at Fast. Jeff Gunther, Hemi Specialist at -fish Auto Parts, created this seal to fix the old leaky rear main seal problem on big block Mopars, as this slanty shares the same main journal size as a Hemi, it's an upgrade Fantastic, follow the instructions for Tee and you will have no problems, it's finally time to put the crank on Royal Purple Max Hard.

Lubricant is applied to the bearings and over 80 pounds of iron are placed in place, the seal receives some RTV and as it is rotated the parting line is inside the block, going from the inside to the outside, the main bolts are torqued to 70 foot-pounds to finish the crank installation, we need to prepare the rear main seal retainer with a little Loctite on the bolt threads and a little silicone on the side seals are ready to go in afterwards After putting them in place we can lock them by tightening them to 30 foot-pounds Last but certainly not least is the crank end plate, now the factory range is 2 to 7 thousandths, this checks out at a comfortable 5 thousandths We're back at it and our leaning tower of power is ready for more parts.

Now it's time to prepare the piston and rod assemblies, first make sure the points of the rings are pointing towards the top of the piston and then the ring. The gaps need to be timed so they don't line up now, if those rings form a line you can take excessive knock, causing pressure in the crankcase and causing the engine to smoke out of the breather. That will also make you doubt your assembly procedure. Here's some Fast Tech: The rings rotate on the piston while the engine runs at an average speed of six rpm, which is due to the scoring angle in the cylinder.

Now a piston ring is unique because it is a reciprocating seal, so it must move freely independently of the piston. To function properly, these are original sealed power replacement pistons that are 440 mil top diameter. Now the ring pack is also sealed power, and as a stock configuration, almost all pistons have a notch at the top facing the front of the engine. The reason is that the risk pin boss is offset on the piston. Here's why they do this. Moving the hazard pin toward the main thrust side of the engine prevents piston noise on cold start. Factories have always done this so that the consumer does not hear a slight clicking sound from the piston skirt in low ambient temperatures.

The rods ride on uncoated King bearings and will be torqued to 40 foot-pounds using extreme pressure lubricant. Now it's time to use Comp Cams' solid flat tappet. It is a unique pattern. with 220 degrees of duration at 50 thousand lifts and has four hundred and forty thousand lift valves on the intake and exhaust, the angle of separation of the lobes is one hundred and ten degrees. Order Summit Racing for a stock replacement timing kit that will make the connection between the camshaft and the Turn now the 7/16 bolt is torqued to 35 foot-pounds. It's an easy installation, just line up the timing marks and continue, we'll apply Loctite high-tech gasket sealant to the Pro Filler Gasket to help prevent leaks and allow for sticking. to the block and stays in place followed by the oil lubricating the chain, the cover can now be fitted and this is secured with ARP fasteners to prevent the mouth of the crank and the inside of the balancer from rubbing when pressed.

A good practice is to apply loctite anti-seize to the surfaces, it will also make it easier to remove when the time comes. These Pioneer balancers are an improvement over the factory part that seals the bottom end and is a failed Pro multi-piece oil pan gasket. You'll spray the cork with more high-tech joint sealant and drop them onto the tray rail. Silicone should be applied where the gasket brake lines are to prevent leaks. The front end seal can now be moved into position. It has locators that lock it into timing. cover the rear end seal goes into the oil pan and is secured the same way and the crankcase drops and is secured with more AR PS with the engine upright we can take the number one piston to true TDC and install a pointer of timing that needs a Small modifications to align, so we will cover the original mark and since this felt will always be on this engine using a rotary file, a new notch will now be made again with a white paint pen and the TDC It is now set to pre-lubricated.

Solid flat tappet lifts can be dropped intoits orifices. They were supplied with the Comp Cams cam kit. A clean deck surface on the block and heads promotes a good valve seal between them and the head gasket. A dropped bead printer seal compound is our choice for On this Slant-6, our valves are reground and will be installed with all new hardware now because our aftermarket camshaft matching valve springs are required On the head, these come with the cam kit and are designed to perform with our highest lift and duration as well as slick. The valve stems are raised with a royal purple set.

Lubricate before sliding them into the guides. Now the new seal can be fitted and just behind it is the spring and retainer making this job easier. It is our Goodson air spring compressor with the locks installed. This set is wrapped. There is no need for expensive fasteners to retain the cylinder head on this engine, the original ones without lubricant will do the job just fine. I like the look of the black head on the red block. It's good, they tighten in three steps from the center outwards. 70 foot-pounds pushrods are a solid design that does not route into the rocker arms the upper valve train is greased from this rocker arm bracket which pressurizes the rocker arm with oil and sprays the friction surfaces with the rocker arm torque We can tighten the valves now since the engine is cold.

The general rule is that thousands are tighter than heat since it is a combination of iron block and iron head. The final is eight thousand on the intake, ten thousand on the exhaust. Perfect, a patterned spectrum. The chrome-plated steel valve cover is the crown jewel of this low-power leaning tower. We are back and we have enough time to finish dressing this 2:25 Slant-6 with all its accessories, letting the engine exhale like a Super. Hooker's offset header with one-inch, 5/8-inch primaries is now a two-piece design with dual two-and-a-half-inch manifolds on the induction side and often a single Hauser aluminum intake manifold that accepts A four-cylinder carburetor must be installed together and held, so having two pairs of hands is a big advantage.

I'm going to push this head in as far as I can. Now a small modification was needed to the inlet itself to tighten evenly with the header flange now the mounting pads need to be narrowed as they are thicker and share the same fastener. the head came with semi-circular retainers and we are lucky they did because they are hard to find otherwise supplying the juice is an Edelbrock 500 CFM four barrel with manual choke and mechanical secondaries to cool a Cardone aluminum water pump now we can mount the heart of the engine in this case it is a Melling standard volume pump a factory distributor like this uses a set of points but we like a little more modern technology so it is being upgraded to this igniter to electronic ignition by part of patron-ax, but none of that summit happened until you see this engine next time, that's because we found it a home in a classic Chrysler that deserves a nostalgic engine.

Just like this, now when the car gets here, we'll put it on the chassis dyno and see how much power its 225 bone will put into the rear tire, then we'll work our magic and see what this is. The modified 225 will do and we expect the range to increase by 25-30%. Acura and Honda VTEC owners will be excited to know that they can upgrade their vehicle with this Accel super tuning trick that the ignition specialist has created. These components will not only make your engine run better but look great while doing it. It comes with a high-performance coil.

Thunder sports coiled center wires and a unique cap and rotor assembly that comes in several different translucent colors in addition to this clear one, so if you want to stand out from the crowd in both looks and performance, you can pick up one of these kits at your local performance parts store for about a hundred dollars. Matco Tools has another cool new item available on the trucks: it's a dual laser. Infrared thermometer that can read from 26 degrees below zero to 1,022 degrees Fahrenheit. The digital display is easy to read and has a distance to spot ratio of twelve to one.

Now comes in a molded plastic case to keep it safe. instructions and a set of batteries you can now pick up yours at your local dealer for just under one hundred and twenty-five dollars. Edelbrock continues to lead the way in innovation for the old small block Chevy with its new e CNC 185 cylinder head. It features a fully CNC 64 CC combustion chamber filled with 2o 20 stainless steel valves and a 600, the exhaust port is of 75 CC and the intake port is 185 CCS. They come fully assembled with hydraulic roller valve springs and 3/8 rocker studs. with guide plates, they fit 1986 and earlier intake manifolds and Edelbrock says they will produce up to 30 more horsepower than a standard set of their high performance rpm heads, fair price is $980 each, well that's it all for us, see you next. time

If you have any copyright issue, please Contact