Lean of Peak (LOP) Engine Operation Explained

May 02, 2020Hello Bonanza fans, today we are going to talk about Lien of Peak

operation

s, how we fly Lien of Peak, how it is different from Richard Piech from anengine

perspective, what advantages there are to flying Lien of Peak and also when it is rich, if Peak can be better. choice, we'll look at some of the theory in a moment, but first I want to show you in flight how we get beak clearing to occur and what results we can see. You may be surprised at how easy it is to change theengine

from rich inpeak

topeak

tilt only one singer is needed control the often neglected mixture knob too much peak tilt is a mysterious issue with some promise of fuel savings , but it can cost damaging the engine, burning your valves, it is cheaper than an engine overhaul like some of the counterarguments to being here at the airport, let's find out what is reality and what is fiction and in the end we will do a little calculation to see how much They can add up to fuel savings over time.Right now we're cruising at 9,000 feet, the outside air is over 4 degrees Celsius, the throttle is wide open, give me 20 inches of manifold pressure and for the moment I'm flying Richard Piech with my airspeed indicator that it shows 143 knots indicated and 165 knots at ESP we have a little tailwind on the ground we are showing 180 knots a couple of instruments I want you to pay attention to are the fuel flow which is the right half of this instrument here that shows how many gallons of fuel come into the engine per hour and we can control it, of course, directly with the mixture control, push the mixture forward to get more fuel, now pull it back to get less fuel and secondly, this which is the digital engine monitor, it has fire graphs where each bar represents one of the six cylinders of my engine and each bar shows two different values.

The top of the bar shows the temperature of the exhaust gases, for example the teeth. How hot is the gas leaving the cylinder after the combustion event? The bottom of each bar represents. the cylinder head temperature or CH shows us how hot the cylinder metal is and then we have these two numbers here at the bottom 13:49 and 305, those are precise digital readings of egt and CH T for one of the six cylinders do you see. a small dot here under the number five means that the egt and CH T readings are valid at installation five, so my cylinder number five currently has an exhaust gas temperature of thirteen forty-five degrees Fahrenheit and a temperature of the cylinder head to 305 degrees Fahrenheit.

I can also Turn on my engine monitor with this switch here from egt and see the HT readings to the fuel related readings that show us the fuel flow and as you can see here we are pushing about fifteen point five fifteen point six gallons per hour through the engine right now and I can cycle through some more related values, like this one here that shows me how many miles per gallon we're traveling eleven point seven miles per gallon right now, similar to your car's gas mileage, except this here is now in nautical miles. Let's go Lena Peak as I guide you through the process.

I want you to see this reading here of the exhaust gas temperature as I tilt the mixture and reduce the fuel flow. The mix knob is down here, so I'm reaching for this knob. and I am slowly reducing the amount of fuel entering the engine, the engine does not sound any different than before, but what you can see is the mechanical fuel flow gauge that is slowly dropping and the exhaust gas temperature, the cylinder number five is going up and I'll keep doing this 1440 43 44 47 and now look at this. I keep reducing the fuel flow with the mixture knob, but the exhaust gas temperature is peaking, hitting a PG t here at fourteen forty-five degrees and now it's actually a reversal. at lower values and that inversion tells us that we are now on the deep side of the peak, the e GT is still going lower.

I'm going to try to leave the mixture up to a point where we get an e GT of about 1420, so about 25. degrees below the peak we saw before and we'll see what that does. A couple of minutes have passed giving me time to sip my coffee and time for the plane to adjust to this new power setting on the

lean

side of the PGD gear, so what happened? changed, the e GT is still around 1420, which is where we had said, 25 degrees below the EDT peak that we observed and we call that 25 degrees peak tilt, looking at my instruments I can see that the true speed here now is of 155 knots so we lost 10 knots our indicated airspeed is 135 knots the ground speed now shows us 171 points our fuel flow has of course decreased because we removed the mixture knob it now shows 12.0 12.1 gallons per hour and let's look at the miles per gallon as well, remember that Before it was eleven point seven miles per gallon, when we hit a peak, now we're seeing much better gas mileage fourteen point three fourteen point four miles per gallon, so we're a little slower than we were originally, but we will use less fuel to get to our destination also the cylinder head temperature for CHT, which was previously 305 degrees, is now stable at 285 degrees, 20 degrees cooler than when we were 18 which in itself is a really nice improvement because when it comes to CHT the cooler is better and that's all it takes, now we're at peak Elina just removing the mix while watching the egt and , at the expense of a little speed, I was able to reduce fuel consumption and increase the range in gas mileage and reduce cylinder head temperature.After a while, let's take a look at what happens inside the cylinder and try to explain why all these changes occur. When we use mixture control, we change the amount of fuel entering the engine without changing the amount of air entering. is the ratio of fuel to air that we change with the mixture control when a lot of fuel enters the engine, we call it rich mixture, when little fuel enters the engine, we call it

lean

mixture with the mixture control we directly adjust a The fuel flow is expressed in gallons per hour or pounds per hour and the engine will actually run well over a fairly wide range of fuel flows while keeping other things like rpm and manifold pressure constant, something that changes as a result of our combination of flow settings made out of fuel. is the exhaust gas temperature or short egt, that is the temperature of the gas leaving the cylinder after the combustion cycle and we measure the egt with small temperature probes on the exhaust deck, like this one here, there is a separate probe installed for each cylinder, so for my six cylinder engine I'm dealing with six separate exhaust gas temperatures for the moment, although let's look at just one cylinder and one egt and ignore the rest in the flight you just saw, at first we were flying with the rich mixture when I gradually reduce the fuel flow with the mixture control remember how the exhaust gas temperature increased slowly and then after reaching a maximum temperature it decreased as I reduced the fuel flow further, so So in a continuous sweep of the mixture control from very rich to very lean, the EDT first goes up. then it reaches a peak and from there it goes back down, that is what is shown in this graph which shows on the horizontal axis the fuel flow you set and on the vertical axis the egt that results directly from that fuel flow.Note that there are no numbers in this. On the graph, the absolute numbers are not that important because what I am trying to explain is that there is a fuel flow somewhere in this range where a maximum egt or maximum egt is reached. Mark it with a bold line here on the chart from there, when we rich or lean the mixture, the resulting egt will be lower either way, there are no good or bad numbers for exhaust gas temperature, the value of Specific temperature itself is not directly responsible for whether you are going fast or slow or whether you are running the engine in a way that favors longevity or not, instead, think about the egt, it is something we can see directly in the cabin and which tells us where on this chart we are trading, in other words are we at the peak of egt?

We are either rich on peak or we are lean on peak and as drivers we have full control over where in this table we run the engine by simply adjusting the mixture control, look at the egt reading, mixture value chain when you are leaning the mixture and the egt. increases, we should be peak rich, if the EDT decreases, we should be peak lean, so the egt helps us determine where we are in this range from very rich to very lean. Next, we will add two additional parameters to this graph, the cylinder head. temperature and power produced Everett Norris Power As before we keep this generic but there are no absolute numbers in place, look at the peaks, inclines and declines and how steep those inclines and declines are, let's start with the horsepower, the amount of power produced by the engine.

It cannot be read directly from any instrument or cockpit, but it can be measured in a specialized engine test and, in addition, a change in air speed can be observed as a result of the change in power, more power means more speed, as can see here, the power curve is quite flat with mixture settings that are on the rich side of the egt peak, maximum horsepower is achieved at a somewhat rich point in the egt peak, that is the point where your engine develops the maximum possible power and, if everything else were equal, it would be a great place to be, but all else is not equal and, as you will soon see, the point of best power is, in fact, very often a very bad place to be in On the peak side of the engine's power, horsepower output drops noticeably as you lean the mixture as much as possible.

See from the steeper angle of the curve on the left side, the slanted side of the graph, I am finally adding the cylinder head temperature or CH T to the graph, this is the cylinder metal temperature and is important for two reasons. of which are related to the longevity of the cylinder, firstly, all metals lose resistance with increasing temperature, so a colder CHT is better, it means the cylinder metal is stronger and more durable, the second part The combustion temperature is the pressure inside the cylinder resulting from the expansion of the fuel-air mixture during the combustion event.

Those two things: high pressure and lower metal resistance are the enemies of all cylinders. If they are too high, they can weaken and damage the cylinder. what we can do to keep CHT slow is a good thing. An important thing to know about CHT is that it changes slowly, unlike immediate changes, it receives the power and for example when changing the mixture, the reason for the slow changes of CHT is the thermal mass of the cylinder. It takes time for all that metal to heat up or cool down and it responds to changes in the combustion process inside.

Remember this when you are looking for changes on the engine monitor, the egt reading follows the mixture change and is virtually instantaneous. while the CHT is lagging and may take a couple of minutes to stabilize at a new value, I will now try to map the two scenarios that we saw with enough light earlier in this chart, we start with a T of, for example, 13 45 degrees Fahrenheit and A CH T of 305 degrees Fahrenheit is not directly known; instead, I'll use the listed speed in our case, 143 knots, as the only thing that can be obtained directly from the cockpit that is related to horsepower.

This was all a result of my fuel flow mixture settings. which as you saw in the video was fifteen point five gallons per hour when I started leaning, the EGT peaked at 14 45 degrees. Further inclination resulted in around 14 20 degrees, the CH T then stabilized at 285 degrees and the indicated speed at 135 knots, all this with a fuel flow of 12.1 gallons per hour, comparing these two scenarios, we were a little slower when we were at the peak, but we were also burning significantly less fuel, we would arrive at our destination a few minutes later, but with significantly more fuel. left in the tanks, so to maximize the tilt of the beak is a great way to fly, plus the temperature of the head of our cylinders is lower, which, as you remember, means we have stronger metal and less pressure inside the cylinder, which is good for the engine.

In this table, when pilots talk about engine power settings, they often express how many degrees of maximum richness or how many degrees of maximum lean they are rather than fuel flow, for example, in the range of maximum, as is shown on the right side of In this table,With a fuel flow of fifteen point five gallons per hour, our EGT was thirteen forty-five degrees, which is 100 degrees less than the maximum EGT of fourteen forty-five degrees, which is why we call this power setting switch peak of 100 degrees the equivalent for the inclination of P. The case was a temperature of fourteen twenty or twenty-five degrees below the peak of fourteen forty-five, so in this case we were running twenty-five degrees of peak inclination, as probably You can see, I'm a big fan of tilting the beak to save fuel. and cooler engine temperatures, but in history, the weather was rich in peaks, it is better.

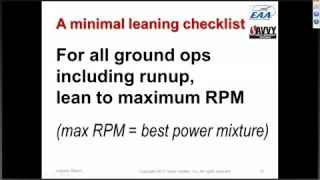

Yes, there are any times when you want the best possible, peak-rich power or speed is the way to go, such as for takeoff, to get the best climb rate, or when it's your arrival time. and a particular flight is more important than your fuel costs, just make sure you are far enough away at the crest site during high power settings to avoid the high CH T and high internal cylinder pressures I mentioned in takeoff, which means full throttle and mixing for rich unless pitched as necessary for high-density altitude. Thinking in terms of degrees of peak richness or degrees of peak tilt is often more significant than the flow of fuel fuel flow alone doesn't tell us much if I just throw out a number, say 14 gallons per hour, depending on what engine I have, depending on flight altitude, depending on how hot the outside air is, depending on the manifold pressure and rpm, that 14 gallons per hour could put me on peak, on the lean side of peak or on the rich side of peak there's just no way to tell just from the number fourteen, on the other hand, saying I'm Running with a 50 degree peak tilt clearly puts us on the left side of the chart, where as you can find 158 degrees rich if peak on the right side to navigate this chart peak degrees of redshift and degrees of peak tilt is very useful.

I'm going to use this terminology now when we talk about power settings that should be avoided due to the temperature and mechanical stress they put on the engine, thinking about the flight you saw earlier where I was cruising at 9,000 feet with wide open throttle. , resulted in 20 inches of manifold pressure on my normally aspirated engine, the engine was making about 65% of its rated power and at that lower power there is no mixture adjustment that would cause abnormal stress on the engine. So you can vary the mixture and fly lean and off-peak, best economy, slightly rich if peak, best speed, or a little more on the edge of peak. for even good speed and a cooler ch TS, all without fear of the engine at higher power settings, things are different, due to the higher pressure inside the cylinder during combustion, the combination of high internal signal pressure and High temperature is especially bad for the engine, so at high power settings you should avoid a mixture that puts you in the area of this table with high CH TS, practically speaking, at high power settings you should have at least 150 degrees rich if at peak, when on the rich side of peak or at least 50 degrees lean. of the peak when on the inclined side of the peak in the middle there is an area sometimes called red box, which is the area that should not work in the red box, it becomes smaller when the engine develops less power, for example when I climb with a normally aspirated engine and disappears completely around 65% power and below due to the red box, it is recommended to transition from rich si peak to lean peak quickly thus avoiding spending more time than necessary in the damaging area associated with the red box, so instead of reducing the mix slowly from rich to lean like I did during the flight I showed you before.

I did this to show you the effect the mix head has on a GT. You should pull the mixture in one quick motion. Not so far is stopping the engine of course, but far enough to get to the lean side of the peak, then you can find the peak of a GT by richening the mixture up to, say, the T-piece, then lean back to the number desired degrees of lean from the peak that is best for your engine and then look for the peak egt from the rich side of the peak let me reiterate something about the red box because it is very important that you understand that it is perfectly okay to run an engine outside of the red box either on the Ridge or on the poor side of the peak, but some people have made it.

It has trouble running the engine somewhat lean, but not enough to be out of the red box again due to mechanical and thermal stress. This is not a good place for the engine; You can quickly transition to the red box to get from one side to the other. another, but don't stop here if you're flying clean off the peak and your CH TS is rising, tune uncomfortably high, your mix isn't lean enough and you need to lean more if that doesn't help you both hit the rich vein peak. and full when done right, you get a lower CH TS than a comparable richer max power setting, as you saw in the flight video above, and if that's not what you're getting, something's not quite right , you may have heard that not all engines can run. peak pitch and unfortunately that is a true statement, why is everything I have told you so far accurate and applicable to virtually every cylinder ever made for any piston engine?

When peak tilt doesn't work, it is due to the fact that you have more than one cylinder per engine, all connected to the same crankshaft, and while the idea is to give each cylinder the same amount of air and fuel, in reality there will be some differences between cylinders to understand why that is important for running at maximum lean. Let's go back to our table, let's say we have a four cylinder engine, everything we reviewed above still applies to each of the four cylinders separately in four slightly different places, this is what they would look like when flying over the crest of the peak, Now I shoot.

The mixture control returns to bring all four cylinders to the lean side of the peak. Look at the power produced by each cylinder in the rich FP case. The power output of each cylinder is approximately the same and that is due to how flat the power curve is in this case. The side of the chart now looks at the same information on the peak lean side because the power curve is steeper here, our four cylinders now produce power with much more variation and that variation in power between cylinders causes vibration or harshness When those four cylinders operate on the same crankshaft, if the cylinders are arranged in two large arranged in this table, you probably won't be able to operate at maximum lean, so what can you do if your engine becomes too rough to run before that it is completely inclined?

On the peak side, if you have a carbureted engine, your options are limited. Unfortunately, carbureted engines tend to suffer from a somewhat uneven mixture distribution and the only thing that can improve things is to apply a little carpet; the warmer air will help create a warmer environment. uniform distribution of the mixture, which may be enough to run cleanly at maximum if you have a fuel injected engine, there is a better option as there is a separate fuel injection nozzle for each cylinder, it is possible to adjust the individual injectors, which which makes the range over which the cylinders In this box much smaller, Gami is the name of the company that makes these injectors and if you have a fuel injected engine that doesn't run much, chances are your gammy cat may help with something else when we say something like tilt at 40 degrees maximum tilt, since cylinders reach maximum EDT at different times, which cylinder are we referring to?

The answer is the last similar to reach the maximum EDT on its trip from regular to lean, as shown on the digital engine monitor in my Bonanza it is cylinder number five and that is why I set the engine monitor to provide the reading of cylinder five in flight. I have previously looked at different engine monitors in different ways to identify when each cylinder crosses PE DT, so check your manual to understand how to best do this with your instrument. The good news is that you will only have to do this exercise once because it will always be the same cylinder in your airplane with your engine at the beginning.

I promised to quantify the fuel. The savings from flying Lena Peak let's use the expected engine life for that and as a human has a tbo of 2000 hours, let's be conservative and assume that we only spend 75% of those 2000 hours on Lena Peak leaving the rest for the climb to takeoff . richer peak

operation

s, remember Richard Piech, we saw 15.5 gallons per hour before, compared to 12 gallons per hour when lean meat was multiplied by 1500, but that represents 50 to 50 gallons of fuel saved over the life of the engine and with an average price of $4.87 in the United States. for a gallon of gasoline according to Yonhap com, that means you save fuel to the tune of $25,000;In other words, when your engine reaches maximum power, the overhaul is free thanks to the Lena Peak flight, which disrupts fuel economy, meaning that off-peak hours are not the best way to operate. all the time, but for my type of flying, it's the best way to operate most of the time. My fuel cost has gone down and my engine runs cooler, saving money on every flight and reducing stress on the engine. interested in trying Beam of Peak for yourself. I suggest you partner with a flight instructor who is already familiar with the peak pitch of your aircraft type and with your engine type, together you can validate or adapt what you have seen here. as needed to make it correct and safe for your airplane, if you would like to learn more there are many other resources available to teach nose pitch and engine management in general, in my opinion the two best are the Pelicans bleed column by John Deakins, available for free. upload on the internet and an engine handling class called advanced pilot that covers this and many related topics over the course of a weekend in a live seminar thanks for watching flying safely and see you next time as you will probably You'll notice that I'm a big fan. of vegan, the egt is still at about 14 20, which we had set with the mixture, not 25 degrees and in the end we will do a little calculation to achieve this and see how much can be saved in fuel and I will continue to do this.

Here and at the expense of a little speed, I was able to reduce the food, so we are a little slower than we were originally, but we would do it, so we are a little slower to avoid the high quality HTS and the pressure high internal. clean but not leaning in love towards the outside of the red walls

If you have any copyright issue, please Contact