Construction of a Massive Ocean Liner | FD Engineering

Apr 23, 2024resistance to steel sweat and experience the Maya VA in poppen Borg is building a cruise ship powered entirely by natural gas the Aida Nova. How has such a complex and enormous ship been created so far? This is a one-of-a-kind, yet state-of-the-art project. State-of-the-art technology is used. Hard physical work and labor are equally important. The builders assembled the gigantic ship from individual modules. These huge propellers will eventually be powered by liquid gas. The biggest challenge is the race against time from the start of

construction

. until delivery the shipyard only needs 20 months and 25 days manual and high-tech work to build a cruise ship Maya vaft is the seventh generation of family ownership for 200 years fishing trollers light ships and cruise ships have been built here 3,500 people work here complemented by thousands of suppliers and service providers with the push of a button a plasma cutter with a flame of 30,000 cuts the first steel plate this marks the official start ofconstruction

of the new cruise for workers Plan by engineers ERS Architects and The shipping company begins the adventure They have 633 days until the scheduled delivery date These are the criteria The finished product must be the most modern and environmentally friendly ship that has ever sailed the world'socean

s The cost of almost a billion of euros the ship was designed entirely by computer, so it is now possible to take a virtual walk around the luxurious decks and restaurants of the designer's Hol deck thanks to Virtual Reality.The wing of the bridge. The side of the ship's control bridge is now visually accessible. At least virtual reality allows planners to move around the site. ship not yet built and see exactly where there is still room to lay a pipe or run a cable, we are actually planning, although the technology does not yet exist while we are planning it or it is technology that is not yet developed to the point. where it could be used right now the process starts with a new concept ship with truly new technology then development groups are formed that will make these Visions a reality this is a high tech ship but the actual shell requires some good old fashioned physical work They are still built in the same way as steam engines in the past or the Eiffel Tower, one steel plate after another being welded together.

The larger plates are joined together in the welding center by a giant robot. An absolute necessity since the dimensions are enormous. The ship will be 337 M long and 42 M wide, longer than three football fields. These plans are becoming more and more detailed. First we have a section, a block and then a floating unit and from two of the floating units we will have a ship just using this one. The section-by-section construction technique may have been able to assemble such a large ship in 18 months. Builders first weld individual steel plates into sections, then put eight sections together to form a block from 90 blocks, finally the new ship emerges.

The advantage is that the builders can work on different parts of the boat at the same time, the men work according to a precise plan, pipes are already being installed which will then run along the roof in the corresponding segments so that the installers do not have to work above their heads. everything is done on the floor a huge rocker then rotates the parts again change of location Neptune vaft in rostok also belongs to Maya vaft here at the same time the rear floating section is built the four engines and the three gasoline tanks will also be installed here in Rostok the two largest tanks are 35 M long and 8 m high, then liquefied natural gas or LNG will be stored inside.

LNG is natural gas that is cooled to -162°, turning it into liquid. The contents of these three fuel tanks are enough for a cruise of at least 2 weeks. The four engines that will drive the ship are being built right next door in this plant. manufacturing for large engines there are pistons as big as beer kegs with piston rings as thick as fingers and crankshafts as long as it is a truck, the crankshaft is pre-assembled by us, the counterweights are bolted to the crankshaft, as well as the connecting rods, all this pre-assembly It is inserted into the engine block, secured and bolted to the base, the new boat's engines are called dual. fuel engines can run on both liquefied natural gas and marine diesel the use of LPG almost completely eliminates the emission of fine particles and sulfur oxides and also significantly reduces the emissions of nitrogen oxides and CO2 an engine is assembled in just a few 5 weeks with only two Specialists, but what is the actual procedure for assembling an engine?

Matías Hatle and his colleague Eric Bush start with a cylinder crankcase that is upside down, insert the crankshaft (the so-called crankshaft) and then turn everything to make the engine work. up and they can place the other components from above first they insert the

liner

s then the piston with the connecting rods the two men then connect everything to the crankshaft which completes the bottom part on the top then they place the cylinder heads and the exhaust system finally hatl and Bush they check the dimensions of the finished product, this is the fine tuning so to speak, Eric measures the piston flanges, rotates the crankshaft with a unit of electrical energy, it must be accurate to hundredths of a millimeter for an engine. of 2000 tons, so we are breathing the flanges at cylinder station one.It is checked once to see how the crankshaft gaps open and this will also be recorded for the experts and this is done again on the dyno to see how the shaft bends or deforms. This is important because otherwise the crankshaft would break under too much tension, it could be too tight or there is a defect in the part or it does not fit correctly, we can detect this through testing, once assembled the engine arrives at the test bench. It has to demonstrate what it can do, how well it can work and also whether it maintains emissions limits and works as cleanly as it should.

The main difference is that we do not produce soot and therefore works very cleanly even in the chimney. there is no smoke the test bench is soundproofed and with all the necessary fire protection equipment this is where all new engines run for the first time the engine starts at exactly 500 revolutions in 3 minutes the exhaust gases are discharged upwards and They measure the cooling water pipes, the fuel pipes and the lubrication. The pipes had to be previously installed after passing all the tests, the operating phase begins. The engine will now run for approximately 10 hours. Parts must be removed from the crankshaft and control shaft, especially the bearings, but also the bushings and pistons after a final test. acceptance of inspection and certification the motor is placed in the paint box here they are given the color that the client has chosen these LG motors are being painted white now the units are ready to be installed on June 30 53 days for delivery The four engines are being delivered, each engine weighs more than 200 tons.

There is a short path to the Neptune ship. Here they are installed in the engine module. Everything that has to go inside has already been assembled by the workers and prepared. The technicians now screw it firmly. the engines to the support blocks 8 weeks later, the first floating unit will be ready soon the noise in the rosto Neptune ship will be deafening as metal scrapes against metal now things get slippery, greasy and oily first the men build a slide to The floating unit must be stable and all welds must be smooth using hydraulic pressure. The first floating unit is pushed out of the shipyard hangar on a film of oil.

The 120M long, 42M wide, three-deck tall hull section slides out of the hangar by CM, finally the hull section comes out. to rest on a pontoon slowly it is gradually lowered and then the engine room module floats on its own September 28 433 days left after more work and preparations the engine room module leaves the Neptune shipyard for poen Borg does well time the tugs pull the module with a short line and then head to KE. If this transport is not an easy task, the huge floating unit has to be towed from Rostok to Poppen Borg in Eastern Freezeland in the numerous locks along the Keel Channel is naturally very narrow. everything has been well prepared, calculated and rehearsed in the end the transport goes exactly as planned here in mayave they have been waiting for the module and they take it to the hangar immediately back to the Neptune yard in Rostok here the men are installing the LPG Meanwhile, The tanks in the second floating unit have received their insulation.

The hallways are ready. The cranes are ready. The final obstacles have been moved to the side. The tank storage chamber with the round bearing housings has also been prepared, so let's connect it. The gigantic tank with its insulation and aluminum hull almost looks like a modern design object, perhaps also the appearance of an airship or a submarine. Now you just have to place the 35 M Colossus in the right place. Daniel Leopold guides the joystick with a firm hand, even if This seems routine, it is not every day that you install such a gigantic tank, there is not much room for maneuver on the sides, routine maybe a little, but never underestimate the danger, one has a lot responsibility now, just a few centimeters from the ground, the notch in the tanks must remain. exactly in the round bearing housings two specialists squeeze under the tank and take measurements repeatedly they are glued to each other underneath they have wood so they are lying on wood on one side there is another sheet underneath so that the tank can move if necessary alone when The last tank is correctly in place.

Can the stuck team breathe easy? They will now have the second floating unit completed so that it can also soon be on its way to Pinborg, 430 km away in Mayave. It hasn't been downtime by any means. As soon as the first floating unit arrived at the hangar, the ship's builders began assembling the blocks. The 500-meter-long production hall is the largest covered dry dock in the world. Here it is welded, hammered and abrasively ground. There are 400 days left for delivery of the block roof panels. Pipes are already being laid everywhere and will then be connected to each other.

A total of 250 km of pipes and wells run along the ship since 2010. Mayaa manufactures its own pipes. In the pipe room there are pipes of all shapes and sizes. Ventilation pipes. Pipes Sewage pipes Gas pipes Heating pipes A cruise ship like this has around 52,000 individual pipes. Specialists work here with welding robots and two bending machines, so that the seams can be welded with great precision and the pipes are worn out. just the right size, but sometimes you need good old-fashioned workmanship. It is also required that this is when experts are needed, as in this case a special AE design was requested that a machine cannot deliver.

This is a job for a friend. He is the man who handles custom pipes of all types and has been doing it for 25 years and alone. He knows exactly how he does it one thing is clear in the end he produces a pipe and it fits perfectly. These are real fixed points, so there isn't much to adjust. It has to be an exact fit. It looks like a complete construction. the blocks in the hull section with the engine module continue at a rate then the dock is flooded the Colossus fleet December 11 the weather is not very pleasant here in the north just below 0° and a strong wind and it started to snow the big door is open and a cold draft is blowing outside two tugboats get to work they have to remove the section of the hangar corridor the second section will arrive from Rostok before midnight ctim by CM the tugs remove the hull section of the corridor the wind It is strong blowing directly on the side of the hull pushing it sideways towards the dock the tug accelerates full throttle to move upwind almost there at the end the ship builders use winches and muscular force pull the hull section towards the dock of a awkward way I work in December, but these men are tough, they raised the gangplank immediately and the work inside the hull continues immediately after dark.

The ship's hull section is secured outside Poen BG's Maya ship while outside, a ghost ship approaches. The hangar is empty. Everything is ready. the doors are wide open the module with the LG tanks has arrived from Rostok and is slowly advancing towards the room the tugboat in the front corrects the course to the left or to the right everything is calculated but still keeps a close watch there is very little room at the entrance the sides slowly move into place now thefront tug has to be pulled outside again, no problem for the crane, it just lifts it into the air and takes it behind the module from outside, another tug brings in the road module which is anchored in position.

The gate can then be closed again and the water is then pumped out of the dock. Work continues immediately in parallel on the outer section of the hull and on the new arrival at the hangar St now things are getting serious everything is in motion 299 days at hand Above the men climb in transport baskets along the outside of the hall and get to their workplaces faster, otherwise they would have to climb 40 m of stairs several times a day. Here everyone knows exactly what to do, of course, we have a construction plan. how the boat is going to be built there is also a schedule and everything is coordinated through the planning department.

We have a site manager who then coordinates everything together with AA, of course they are constantly checking what we are doing inside or outside, up or down everywhere. cables are being laid, panels are being placed and new materials are being brought into the passenger areas, work is continually being done on the prefabricated cabins, which are manufactured by a subcontractor during the day, brought here in the afternoon and They install at night. the decks have already been prepared for the cabins some windows have already been installed the insulation is in place the floor has been sound and heat proofed in just a few months this will all look like this but until then there is still a long way to go This is the elevator now but this is what passengers will see in the future The clock is ticking 292 days for delivery Since 2007 Maya Vaft has been manufacturing passenger cabins using a state-of-the-art assembly line.

First step: the door, the door lock and the walls of the cabin. There are 22 steps, so 22 workstations. It works much like an automobile assembly line. The conveyor belt. It runs at 3.5 mm/s and after just 20 minutes a finished cabin emerges from the lobby, complete with TV and reading lamp. Sandra Ventur and her team check whether everything is exactly as the furniture should be. The parts, whether they have been assembled correctly and the dimensions. if the power strips have been placed correctly if there are gaps errors scratches and all that this is the side where the balcony area will be and that is the side of the walkways the cabins finished and ready to be installed are delivered by truck to the right aisle Next to the boat, this is a standard cabin and will be installed on the boat immediately.

We are at a pace of 30 minutes per cabin, which means that from the start on the podium here we have 30 minutes to get the cabin into position. and be ready for the next one, so in a 30 minute, 30 minute period, men really have no time to waste. The cabins are lifted with a crane, aligned and then pushed into the correct position using muscle power. The booths are aligned using the old plum line we use. use a plum line to align them not a laser because someone could bump into it and then everything is crooked when everything fits workers weld the cabin frame firmly in place you can see the inside very well as everything is there from the chair, the trash can, the mattress, the bed, everything is there, it makes the job easier, especially later, when the cabin is finished.

The construction of such a gigantic ship is extremely complex. There are literally millions of individual elements. 2,500 km of cable and 65,000 square meters of carpet. Everything has to fit perfectly. arriving at the right time at the right place How can someone control the process and maintain an overview? It really starts with deliveries. All parts should be checked and inspected for correctness and integrity before installation. by the subcontractors then the inspection process begins first with the internal courtyard then with the courtyard and the owner in this case AA and finally the certification of the classification inspector then when everything works everything is fine it would be nice if we could just walk through the walls and visually inspect each pipe and cable channel, but we can do it in the virtual reality room, even during the planning phase, experts can visualize the various rooms, the execution of construction work is digitally transferred to a 3D model The engineers during the day are converted at night and entered into the system when the production worker arrives the next day, he has the most recent data at his disposal, so In this way, possible errors can be avoided or corrected from the beginning in the planning phase or, at the latest, during the planning phase.

Construction planners can turn the entire ship around, open the floor and check the position of the tanks, they can even go directly inside the tanks. The same data we see here can now be communicated to all employees. 291 days to deliver an alarm signal. The strongest crane for ship Builders, the Imperial Eagle can carry up to 800 metric tons on its four hooks and hanging from this crane is an important element for the future of the ship. The Atrium is so far just the shell a huge steel structure that It will become a 360° theater with a laser show with LED walls and a retractable elevator stage for performers.

Logistics are really important, for example in the theater, here the equipment for the rising platform and the LED video wall are already installed, if you wanted to do it later you would have to do it. bring them on board little by little and here it is pre-installed on the unit, but now the huge steel structure is still hanging on the crane, first it has to be taken out of the block construction site, placed to the millimeter in the corridor section and fixed precisely . instead now all the cranes have to move back, only then we can come here with the block, then all the cranes pass again because the block is too high, then we come back here with it and finally we can place the block on the ship, it is like the Tetris game for giants, of course, safety has top priority, no one can stand under the hanging atrium, slowly and carefully, the crane operator maneuvers the gigantic structure above the ship into the correct position, then it's time leaving and the workers raise their safety equipment.

They approach The Edge carefully, then weld the tow hooks with several hydraulic presses, move The Atrium to the correct position and then check again in another part of the yard, later they are working on the roof of the Future Beach Club. It will be the main public area with several swimming pools and bars. It is a complicated construction and will then be covered with a transparent sheet and has to withstand all storms and ship movements, even in rough seas. The pool water slide is ready for installation. of specialized companies and subcontractors work on such a gigantic ship contributing their part to the overall picture.

All this work has to be perfectly coordinated. Anyone who has built a house knows how difficult it can be. What must it be like to build a cruise ship now? mid-February 270 more days until delivery the shipyard is preparing for an important step the dock gate will soon be closed because a wedding is approaching after all the blocks of the second section of the corridor have been welded into place the section aft is the first To leave the hangar to allow this, the ship builders flood the dock again, then the center section that has been outside until now returns to the room, followed by the aft section and both are aligned before the Workers can weld the 19 covers and the top.

For 42 M wide modules, you must first place both in the correct position to the millimeter. The men are working on all the decks at the same time welding, measuring and making all the preparations to finally join the two halves of the giant ship on which they have been placed. here in the dry dock that will be flooded again, we then bring the two halves together and then bring them to their final position in the middle of the 500 meter long hangar is the bridge of the new cruise ship, this will eventually be the control center of the AA Nova So far it looks like a kind of huge steel cake full of holes inside.

Construction work has already begun, only in the control room, 30 km of electrical cables are going to be laid. What we see here now are the supply cables for this section electricity light internet that sort of thing, but the most important cables for the ship's controls are installed later, this is because the control cables can only be laid and connected to the machines after the bridge has been laid On the ship, the dock is now flooded, the two sections of the ship now float into position and then, by means of spot welding, are tacked together, the exact alignment of the enormous holes, each of which weighs 20,000 tons, It is carried out using a sophisticated ballast tank system.

They are in the port. and to starboard water is pumped in and out so we can keep it balanced. It is very clear to see that the ship still has an indentation in the middle. The ship's builders now have 1,000 M of welding ahead of them. First, a ceramic guide rail is placed on the then they can begin the actual welding, the men gradually work their way down from deck 17, but there are still some steel plates that need to be aligned first. Now we put the starboard press on it and then put them together correctly so that they fit well.

Nice and tight, a hydraulic ram has a pulling power of up to 50 tons and at any given time, sometimes four or five are used at the same time, the two pieces are put together and then workers do the welding in the welding room. 125 M width of more structural parts. are ready and waiting, in addition to the bridge, there is also the Four Elements Section with the Climbing Garden, here passengers will be able to climb to lofty heights above the treetops, this is what it will eventually look like, all of this still needs to be installed on the boat, but something very important is still missing the four complete decks with the bow and bow thrusters.

Block 69 is also missing. It is located between the bow and the center section and weighs 500 tons. He gets off and then lines up. The block will be installed in a single shift. The blocks are on a sliding system, they are lifted, placed on hydraulic sliding cars and pushed to the correct position. The bow of the AA Nova is designed to cut almost vertically through the water. There is only a small bulbous bow afterwards, this will barely be visible when below the water line, the entire front section is also put into position here it is also tacked first to secure the bow the weld looks like a freshly stitched wound While the finishing work continues inside, the floor is laid, there is an insulating layer on the steel plates and on top of it, a thin sheet of steel is a kind of floating floor.

In the kitchen area of the restaurant, a self-leveling screed is laid, as Whether in the construction of the structure or in the interior equipment, General Director Sven FAA has to be on top of everything today in a meeting with the ship's architects. In an equipment room, the interior designers together with the shipyard decide the shapes, colors, dimensions and materials. Then, the various contractors have to implement the plans. If questions or difficulties arise during the installation work, the team will meet as today, the construction materials used for boats are generally of higher quality than hotels. Zig Shindler is one of the most sought-after ship architects.

Doing interior design for a hotel is easy compared to what we do here. Here we work with a completely different range. of materials but in very limited spatial dimensions a ship really uses every millimeter is not the only quote from F today later it goes deep into the belly of the ship this week the first engine was tested it had already been commissioned on the test bench but Only here you can really see how the engine interacts with the other components here in the main engine room. There is still scaffolding above the main machine. The ceiling is still being painted.

The last works are being finished. Everything will be torn down in 2 weeks and then we will have it complete. access to our main engines and individual cers crane operator reinold vills on his way to his shift today he will install the bridge he is the man with the amazing instinct Williams is the only one in the shipyard with his own lift that takes him here instead working 60 m above the floor, quickly explains the cabin here on the right side are the levers for the hoists the left is for land in the middle is the main elevator the right lever is for the beach we differentiate between sea and land with his centimeter-controlling crane Williams places the 345-tonne component in its exact position then the welders take over.cargo and attach the 50 m wide bridge to the ship a few days later a distinguished visitor appears on the bridge Captain Boris Becker inspects his future workplace the wing with the ship's controls from here you will have the best view when docking in the port there a lot of space on the bridge exactly 500 m2 here is the carpet the bottom layer is already installed and That's a big step.

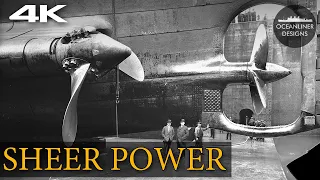

I remember four weeks ago, when the floor here was still open, the bridge will be guarded 24 hours a day, but it still needs a little. Furniture, there will be two chairs here on one side, usually the captain on the other side. a place for a pilot when necessary, in front two officers, the navigator and the co-pilot, who can steer the ship themselves. May 4, 196 days to deliver another important milestone in the construction of this giant cruise ship. Now the installation of the two aipods is imminent the azipod is a nacelle that rotates 360° with a propeller attached this is what drives and directs the boat which used to be you only had a propeller a rudder and a bow thruster that you would use to move the stern now you have azipods, you can actually get the force of the water at the exact angle you want, of course a huge advance, now you can steer the boat much more precisely.

It is still connected to the aaot is a test propeller. This propeller does not have blades yet. a zero Drive propeller with it we can test practically everything in the shipyard without moving the ship with a crane the 12 m long 230 metric ton aaod is placed under the stern the port side azipod is already mounted with a so-called floor car low they take the second engine to its position on the starboard side where its location is already prepared at the stern, there is not much room for maneuver, the challenge is to assemble these 230 metric tons that we see in the background to the exact millimeter so that we do not have much space to play , we have to go under and we have about half a millimeter of tolerance on the guide pins.

It will be hours until everything is aligned so precisely that the guide pins fit perfectly and the retaining bolts can be tightened after that the electronics will be connected May 30 170 days until first delivery the entire AA Nova has water under its keel is now a real ship The ship floats 100 40 m to a new position here it is given the AA fleet typical pursed lip logo its 250 S M surface area will require 622 L of paint in total. 250 tons of paint and corrosion protection are applied. The 622 L for the artwork on the bow is actually just a drop in the

ocean

but of course it is important for the passengers.The workers are now in the process of assembling the propellers. Seven men hold the five fins on the right azipod. Their contact surfaces must be meticulously clean so that they function as best as possible. Each blade weighs three tons and each propeller has a diameter of 6 m. On the same night, everything is finished. The ship's propulsion is ready. August 11. There are only 97 days left to deliver. to all. One is very concentrated. The ship is still in the hangar. There are still a thousand different things to do. Workers are painting the 360M anchor chain in a length of 27M.

The chain is always intact. So is there a link that can be opened? The so-called cane shackle. This is really the only thing that connects the chain every 27M. Only at these points can the chain be separated. The installers are installing the exterior balconies. Certified drivers are underway. around the boat checking measurements recording this area has passed its final inspection so next time there is a lot going on in the galleys too, fools are being installed. The Atrium gets its last few wires and connections for me, the challenge is definitely collaborating with other contractors because everything has to fit together, so a lot of things need to be coordinated across numerous spaces.

Craftsmen are laying tiles in between all the construction work. A large amount of skilled labor is required. This carpenter has spent weeks making a continuous railing for the stair railings he has completed. 400 m and another 1.3 km left August 18 90 days until delivery The final stretch is in sight. The changes in the Carters of the cabins are clearly visible, but there is still a lot to fix. Briefing sessions for the first crews arriving at the shipyard. This advanced group will clean the first of the 2,626 cabins on the bridge. Electronic connections to the engine room and iPods are being tested.

The beach club is also advancing. 1,1600 m of special UV-permeable sheeting is being applied in the roof a job for industrial climbers August 21, 2018 only 87 days left until delivery the ship finally surfaces, it takes 2 hours for the giant Oceano to be completely removed from the 500 meter hangar and then prepared in the so-called birth of equipment here Preparations are made for the naming ceremony 10 days later, everything is ready. The new

liner

is officially named after her at the beginning of October. There are 38 days left until scheduled delivery. The ship shines in the sun from outside. She seems almost finished, but inside there is still a lot of pressure.There is work to be done on top of everything else a floating hotel needs to put up for sale. Food is being loaded and arrives on board. Dishes need to be unpacked and distributed. Office chairs are being assembled. Everyone is doing their part to help. fire zones 5 and 7 are where the chairs will be placed check how many desks are ready how many offices are accessible meanwhile on the bridge the radar is checked and one of the pools with water is tested thousands of dishes are being stored and this is the most efficient method cooking tests in the galley to test the technology and ensure that the crew on board do not go hungry, the carriages to the cabins are at least finally finished and the theater has been totally transformed the lifeboats have been raised to on board by a crane below deck Specialists connect all the cables for the television studio on board we have 200 lamps that still need to be installed this is a television studio so good lighting is extremely important this is how it looks now and This is what a studio for an audience of 400 live shows will be produced and broadcast from here in a few weeks.

It is the world's first television studio on board a cruise ship. Meanwhile, technical acceptance procedures on board continue unabated. The pressure is mounting with just over a month to deliver the ship on October 9. leaves pinborg for Ames hoen in the Netherlands the rest of the crew embarks here the interior fitting out work is almost complete the restaurants are in operation and engine room 2 has been fully inspected and, with the approval , this is one of the four LNG units 15,440 kilowatts each at 514 revolutions the senior engineer Gad Hoffman together with the LG engineer check all the settings once again the gasoline tanks are located behind the wall with so much fuel gas in the ship appropriate precautions are needed the safety standards for these tanks are incredibly high for example we have gas detectors and special ventilation systems and you can see here that the tanks themselves are complex but very robust, they are also surrounded by a controlled nitrogen atmosphere and all that was left behind here on December 12 Brima hoffen deliveries 21 days later than planned complexity and new technologies have taken their toll, but it is a ceremonious occasion: flags are exchanged, the German flag is lowered of the shipyard and the Italian flag of the cruise company is raised.

This is a very special moment for Captain Bar Becker for the first time. He will set sail with his new ship this afternoon bound for Lisbon, 4 days later in the port of Lisbon. Bramer Hoffen's crossing via Roddam to Portugal went smoothly. The next stop in Tenera is finalizing preparations. The new crew members are getting familiar with the ship. in the Panorama Suite the beds are made and the drinks are in the refrigerator the terrace is ready for the first swimmers 20 different cabin categories leave nothing to be desired for the first time there are also C cabins for singles 17 restaurants now await the arrival of the guests Also the climbing garden, the outdoor slide, the spa area with its saunas and numerous indoor and outdoor bars, the theater is ready for its grand premiere, the actors and singers backstage are preparing for the show, everyone is very nervous until now, they have only rehearsed on land.

In this new scenario on board, everything fits and feels totally different. Yes, I'm very excited. We were actually working hard and couldn't wait to perform this in real costumes for a real audience, so we're really excited because we're ready. So much for this, let's rock that boat a living room concert with a virtual band, which means the band is playing digitally on the LED screen but the singers are performing live in the foreground the entire show is specially scripted for this new technology the choreography is the work of Cirus Benjamin Pring and Alexa Uvarov my imagination was even surpassed when we were first in this room, scaffolding everywhere, steel work lights, you could already guess what it would become and Of course, this new inspection there are still no photos of the new ship at sea this is a job for the skynamic team these Berliners are stars of the drone scene today's job is to capture the AA Nova at full speed you have to go relatively far away so that the boat appears in the image and Of course, then it is difficult to continue seeing the Drone.

You always have to keep the Drone at a certain angle towards you and at the same time control it around the boat. The last screws are tightened, whether in the elevator or outside. Things are being polished everywhere. and are cleaned to make sure they look their best and gradually, even the smallest faults are removed from the list below the deck, the dry cleaning service has come into operation. Clean clothes can be delivered to each crew member automatically because a chip has been sewn into each piece. of clothing you select determines the amount you order and the system also knows that you have picked it up and can wear it until you return it the cooks work on the menu selections the pizza The baker is getting familiar with his pizza kitchen the cleaning The machines for The kitchen floors have been loaded and the crew restaurant is also ready.

The crew comes from over 50 countries so the kitchen has a variety of food options to suit all tastes, everyone can eat whatever they want and that's beautiful. I'm also a fan of Indian Tandoori food and that stuff that colleagues usually display here, but Asian is also good or there's also mint fillet with mushroom sauce to be sure the 17 restaurants on board have enough for food for the international crew of 1,500 people and more than 5,000 guests. Food supplies will be brought back on board in tenifa. The ship has 24 refrigerated and non-refrigerated warehouses with a total of 4,000 sars M.

The ship arrives in Tenifa. The captain and crew are finally in place. destination but at the same time they are back to the beginning because now Aida Nova's journey across the oceans really starts from the first cut, it took 660 days to build the ship,

engineering

skill, perfect organization, the craftsmanship of the guard The ship and The Cruise Company have all contributed to making this possible: tomorrow the first passengers will arrive on board and then it will be time to set sail for the first cruise ship powered entirely by liquefied gas.If you have any copyright issue, please Contact