Powder Coating - Top 10 Powder Coating Tips for newbies

May 01, 2020How's everybody? Hi, I'm Dan with a tire, right. Let's make a quick little video. It may not be fast. I may ramble a bit, but these are the top 10

coders and why I am. I'm getting into this because I've seen a lot of videos with guys who are on construction channels or building something, so they buy a hobby gun and

coat some of them. They're giving you all this advice. I've seen a lot of them and I'm like no, don't do that, no, don't do that, so I just want to do a quick video with 10

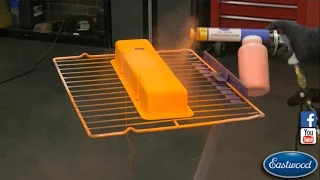

and this might be whether you're using an Eastwood Harbor Freight gun or a Spectracoat Columbia

gun or something like that, those entry level guns, number one is talking about amperage, if you have a gun that can handle that amperage like an Eastwood gun, there's a 1 set it to a setting 2 setting two is your high setting go ahead and powder coat with that as much as you can if you're doing a second coat turn it down so basically you're taking those high charge particle systems and there's Let's take it down so there's less Faraday, there's less reverse ionization, all that kind of stuff, so we just upgrade our personal weapon, which is a game up from Dima gum kheema and it does it automatically for us, so now It controls the amperage a lot automatically. of people say reduce their kV, which is not right.

tips

I have for newpowder

coders and why I am. I'm getting into this because I've seen a lot of videos with guys who are on construction channels or building something, so they buy a hobby gun and powder

coat some of them. They're giving you all this advice. I've seen a lot of them and I'm like no, don't do that, no, don't do that, so I just want to do a quick video with 10 tips

that I have for people who are just starting out or just getting into powdercoating

and this might be whether you're using an Eastwood Harbor Freight gun or a Spectracoat Columbia coating

gun or something like that, those entry level guns, number one is talking about amperage, if you have a gun that can handle that amperage like an Eastwood gun, there's a 1 set it to a setting 2 setting two is your high setting go ahead and powder coat with that as much as you can if you're doing a second coat turn it down so basically you're taking those high charge particle systems and there's Let's take it down so there's less Faraday, there's less reverse ionization, all that kind of stuff, so we just upgrade our personal weapon, which is a game up from Dima gum kheema and it does it automatically for us, so now It controls the amperage a lot automatically. of people say reduce their kV, which is not right.We have done a lot of testing with this after speaking with a gheymeh representative and what they do is keep their cavies as high as possible because that is what gives their particle the transfer efficiency to get to the piece and not fall to the floor , micro amps are the type of amplification that makes you crazy and static I guess, and when you get into those parts it wants to bounce and come. back off, so they recommend lowering them and not kV, but many people have heard kv k v kv and that's what they still preach today.

Try it if you can control the microamps, leave your kvs alone. put down your microamps and give it a try, leave a comment and tell us what you think, if it worked you owe us a thumbs up, next is preparation, preparation is everything, so most people who have ever painted something or applied a layer of dust and have been refinished. anything stained, any preparation is everything, as long as you clean the piece completely you won't have any problems and what we recommend, if you can, is to sandblast it, then remove the gas and then blow it out well with air. it's hot, let it cool and cover it.

What this does is bake all the contaminating oils, grease, and anything on the surface out of the pores and aluminum, and then allows you to coat a clean wheel. There are some people shooting gasoline and explosions. Again, my concern with that is that when you're cleaning that dirty part, the dirt, grime, grease, whatever that's building up in your middle and then you fly over it again, if you have a blaster of a just use, like if you're outside, sanding, that's probably fine, but for a salvage system you don't want to do this, so I don't think you need to get rags and clean them with acetone, especially if you're starting with a new piece, just polish it with sand, put it in the oven and let it bake. take it out, let it cool and then cover it, we do this with all aluminum, steel, all the number three is the baking time, so a lot of people say, put your part in, let it come to the fourth or set your oven to 450, put your part. once it comes out, turn it down to 400, wait 20 minutes, take it out, this is not accurate information people, what the text sheet will tell you is how long that part needs to cook at a certain temperature, this is not the powder, this It's a part, so it's not once the powder flows, it's when the part reaches the specified temperature, say 400 degrees, then you can cook it for 10 minutes, so the best way to judge this is to get a good temperature gun .

We use a Dewalt gun, it is very good. you can control the EMS which is the reflective ability of the piece you can set it to fixed loom and I do all kinds of things with copper so I usually have it in the links below so check it out but always follow the manufacturer specifications. powders you only do it 385 about 400 about 410 I mean they are all different so you have to ask for those text sheets number four would be to control your air and as many of you know if you have seen my videos people comment on my air and yes, that's a problem I have on my own, but I know I need to do it, so if you're an Eastwood gun or a Harbor Freight gun, you control it, you have to have a regulator on your line regulator gun when you pull the trigger, you can do this without gunpowder you need to adjust it down you shouldn't use much 4 psi the less you can get by with Ashlee the better so I think usually 3 to 5 pounds of our psi will help you but you need to play with it so on the last step put the gunpowder, pull the trigger and adjust the pressure.

You don't want it to blow out a ton of air, knock the gunpowder out of the part it was put into, and blow out another gunpowder. right after, so be careful with that, watch my videos, you'll see what I'm saying. I usually shoot a ton. We just got a new weapon that will take care of that. I used to have to go around and turn a lot of marking and adjusting everything for each powder. Hopefully with this new gun it will be a little more automated, but that's something you'll have to do. Next tip number five would be your turf, so many of the pros we're taking. 8 foot copper rods, we're drilling a hole in our floor and we're jamming that thing by hitting it with a hammer, knocking it down, we attach as thick an electrical cord as possible to it and then we attach it to our cart that's holding our piece or we secure it to the piece itself now if you have a clamp on your piece and a coat of powder paint, remove it at the end, dust and cover the clamp area, no problem, but that's very important.

You can get by with some really bad weapons if you have good terrain, even if you can do it outside your building, as close as possible to where they spray you and then pull that line and ours is in our booth, literally in our booth. you want it as close to piece number six as possible, complex elements, so when you're photographing something that's really difficult, has tight corners or recessed areas, always shoot those difficult areas first if you have to and I know you're going to have to do that with these lower level guns heat it up a bit, no more than 200, don't put it in, take it to 400, take it out and spray it because you will build up too much powder, it will run, there will be too many Mills, you won't be happy, so always 200 or less 185 if you can get by, distribute those difficult areas first, work your way to the easy areas, which brings us to flocking number seven, if you're asking, you should do it now. a professional who has a good gun, you will never need a hot flock now that you are shooting with an Eastwood gun, you will probably have to heat that part a little, unfortunately it is part of it, but the ground will help prevent it. a lot knowing how to shoot will help you a lot, the airflow will help you a lot, but yes, sometimes you will need to heat the piece up a little bit, but again, I never recommend 400 degrees, try to stay at 200 or less, 185 is. best number eight, does it need primer?

So with us in our store we don't do a lot of priming. We do it if the casting is bad in aluminum. We do it if the client requests it. We do it if the pieces are seen a lot. from outdoor abuse, what primer gives you the most corrosion resistance and we always do it still, if it's not aluminum, chances are, unless you request it as a customer, we'll put primer on it because it gives you that extra resistance. to corrosion. so we're not going to get into epoxy zinc red oxide or any of that kind of stuff we're just going to tell you the basics at this point we can do another video on equipment needs so to start off Eastwood actually has a package. where you can get an air gun and it's not that bad, those are your basic needs, obviously, powder with powder, so you need your air supply, an air compressor, you need your oven, you need your coating gun in dust and you need your dust, obviously, We will have a part, if that part is new, primed and ready to go.

Just spray it on, put it in the oven. Ready. If you need to remove it, you're going to need like an aircraft stripper, spray it and then scrape it off, wipe it off and then spray it or you might need to sandblast it and that's what I recommend. It's the easiest and cleanest way to do it if you can afford a sandblaster or take it to someone like me. I do it. because people sandblast the pieces all the time and take them home and powder coat them. We don't care, you know, we're just helping you, so find someone who can sandblast it, it takes a lot of work, make sure they're touching it with their hands afterwards I guess we had big things.

Sam, bless them, they come back with fingerprints. Your powder won't stick. I promise it will lift wherever that fingerprint is, so just make sure the part is clean. gas and all that number ten where to buy powder so when you're new the number one best place to go is prismatic powders dot com. I buy tons of powder from their distillery. They have custom colors. They have illusions. They have candy. Metallics, I mean, they have a variety and it's quality powder. They are by far the best place for a small person to go. Columbia Coatings, which is actually where we bought our booth because we're professionals, but we're beginners. professional level if you know what I mean they are reasonably priced for someone my size they are still very expensive for the home type but Columbia powder is reasonably priced you can buy them in small quantities check them out or powder by the pound. we buy a lot of stuff from them and I think it's powder by the pound, or google it.

I'm not sure, but that's where those three places I would go are, so I hope these ten tips have helped you a little. I know I could have used them. There is so much information available. I am powder coating and how to do it and as far as I know this is the best information I have at the moment. We have done a lot of classes. I have a lot of dust. coating manuals and things like that and you know, we're trying to be one of the most professional places in the state of Iowa, we don't do jump work, you're not going to bring your part in here and it's going to come out like garbage.

I won't let it go if it's rubbish, so we're always trying to learn more, so we're happy when people comment and help us, like with our dust problem, as far as how much we're spraying, we don't take a fence to We don't really know what's going on, but at the same time we need that kick in the butt to make sure we're doing it right, so I hope they got something out of this if they give me that thumbs up. above show me you're here if you have a comment or question leave it below we'll be happy to help you we'll be happy to respond we try to respond to everyone unless you're being inappropriate and as always make sure you subscribe We're at the moment I think 169 and a lot of people are telling me They have sent private messages and told me: why don't you have thousands of subscribers?

Don't know. I guess YouTube is fighting us. I don't know, but we. I hope to blow it up and we hope to continue helping you so see you in the next one thanks for watching.

If you have any copyright issue, please Contact